Thermography has proven its worth as a tool for preventive maintenance, in order to monitor mechanical and electrical systems or production processes. In the field of research and development, Testo thermal imagers are also used to examine microelectronic components.

1. Regular checks in electrical maintenance: Testo thermal imagers allow an evaluation of the heat status of low, medium and high voltage systems. Thermographic images lead to early recognition of defective components, so that the required targeted preventive steps can be taken. This minimizes the dangerous risk of fire and avoids costly production downtimes.

2. Support in preventive mechanical maintenance: A reliable early recognition of threatening damage to process-relevant system components is necessary in order to guarantee the security and reliability of the machines. A high level of heat emissions, especially from mechanical components, may indicate an elevated level of stress. This is caused, for example, by friction due to faulty adjustment, component tolerances or a lack of lubricant. With their high temperature resolution, Testo thermal imagers provide an exact diagnosis. Critical heating conditions can be directly detected with the alarm or isotherm function, and countermeasures can be introduced.

3. Quick, easy filling level checks: Level control in sealed fluid tanks has proved to be a useful method for avoiding machine damage and therefore production losses. If, for example, the fluid in coolant tanks falls to a dangerously low level, machines are no longer cooled correctly. They run hot and may fail. Often, an automatic level control regulates the level of the refrigerant and issues an alarm when the filling level is too low. However, the automatic control can also fail. In this case, a regular look through a thermal imager will also help.

4. More reliability in quality assurance and production monitoring: The thermal imagers from Testo ensure precise situation analysis, thus supporting process monitoring and product quality assurance. In addition to foreign bodies in production processes, anomalies in the heat distribution of components are also recognized at a glance, quickly and without contact.

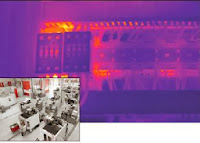

5. Inspection management in large production systems: The regular inspection of machines and switchboxes in large production systems is time-consuming, but indispensable. During such inspection tours, similar measurement objects often have to be monitored, resulting in many thermal images of the same type. Previously, in order to be able to allocate the measurements clearly to the different measurement sites, complex lists needed to be kept, or a voice comment added to each individual thermal image. With Testo SiteRecognition technology, measurement sites are automatically recognized and the resulting thermal images correctly archived.

Watch this space for more thermography applications in industry.

You can write to us at info@testoindia.com for more info or visit www.testo.in/870